USE DISCOUNT CODEEXPERT30TO SAVE $30 USD

Flex/Rigid 3D export

JohnsonMiller , 03-23-2020, 04:22 AM

Hi Guys,

I am dealing with a rigid/flex PCB, setup and design is done in the Altium, and it is final and ok. I am going to export 3D when the flex section is in the bent form. If I choose STEP, it exports without change and is ok, but when I select 3D PDF, the output is in the flat form not in bent form, even though Altium 3D view is in the bent form!

Since the report in PDF is more convenient, wondering do you have any idea how I can fix this case?

PS - Hope all members of this forum, your family members, and relatives are safe and away from this new little ugly guy, COVID-19! Take care!

Regards,

I am dealing with a rigid/flex PCB, setup and design is done in the Altium, and it is final and ok. I am going to export 3D when the flex section is in the bent form. If I choose STEP, it exports without change and is ok, but when I select 3D PDF, the output is in the flat form not in bent form, even though Altium 3D view is in the bent form!

Since the report in PDF is more convenient, wondering do you have any idea how I can fix this case?

PS - Hope all members of this forum, your family members, and relatives are safe and away from this new little ugly guy, COVID-19! Take care!

Regards,

robertferanec , 03-24-2020, 02:47 AM

Hi @JohnsonMiller. Honestly, I do not know

PS: Some time ago I wanted to create an open source FLEX project - but Altium was not ready for it and same as you, I experienced number of things what I could not figure out or they have just not been supported in Altium yet. So, I gave up on FLEX project and waiting until they make better support (I had a lot of troubles with bending - e.g when bending was in the middle of PCB, it just didn't work, also, there was no support for stiffeners - not sure if they fixed it by now ...)

PSS: Take care

PS: Some time ago I wanted to create an open source FLEX project - but Altium was not ready for it and same as you, I experienced number of things what I could not figure out or they have just not been supported in Altium yet. So, I gave up on FLEX project and waiting until they make better support (I had a lot of troubles with bending - e.g when bending was in the middle of PCB, it just didn't work, also, there was no support for stiffeners - not sure if they fixed it by now ...)

PSS: Take care

JohnsonMiller , 03-27-2020, 03:23 AM

Hi Robert,

Which software do you prefer for rigid/flex design?

How we should proceed to order the rigid/flex design? Is the ordinary GERBER or OBD++ is enough?

Best

Which software do you prefer for rigid/flex design?

How we should proceed to order the rigid/flex design? Is the ordinary GERBER or OBD++ is enough?

Best

robertferanec , 03-27-2020, 07:58 AM

I have only designed a few flex pcbs - it was mostly like a standard PCB (maybe hashed planes and rounded corners), just flex stackup. At that time I used ODB++ because that was what we used for all boards, but I believe they should be able to manufacture it also based on gerbers.

JohnsonMiller , 05-10-2020, 06:50 AM

I was wondering in a Flex/Rigid design shall I mention rigid and flex parts somehow in mechanical layers, or GERBER files will include the layer detail?

beamray , 05-11-2020, 01:46 AM

Hey there! Make sure that you have one of the rigid parts fixed (or 3D fixed , Altium guys keep to rename things). You can do it from board planer mode (button 1).

Gerber is just raster or vector image. ODB++ will do better. But I highly recommend to do the following:

Make A Fab Note mechanical layer

put a stackup table with board map (you can do it from place menu)

On this same layer do comments with arrows: it should help to identify flex and rigid parts.

AND I usually draw lines where flex part begins and make such comment. (I had done many rigid-flex PCB last year.)

Gerber is just raster or vector image. ODB++ will do better. But I highly recommend to do the following:

Make A Fab Note mechanical layer

put a stackup table with board map (you can do it from place menu)

On this same layer do comments with arrows: it should help to identify flex and rigid parts.

AND I usually draw lines where flex part begins and make such comment. (I had done many rigid-flex PCB last year.)

JohnsonMiller , 05-12-2020, 03:53 AM

@beamray , Thank you for your reply, your experience is very valuable.

- I would like to know which design tool you are using for flex-rigid design?

- Can you suggest a decent flex-rigid manufacturer in the EU or China?

- My design is simple and only two-layer on both flex and rigid area, do I still need to be in touch with the manufacturer for stack up data?

- I have routed the board with round traces, and straight-line at the bending point, what about board edge shape, do we need to make it round or 90 degree is ok?

Regards,

- I would like to know which design tool you are using for flex-rigid design?

- Can you suggest a decent flex-rigid manufacturer in the EU or China?

- My design is simple and only two-layer on both flex and rigid area, do I still need to be in touch with the manufacturer for stack up data?

- I have routed the board with round traces, and straight-line at the bending point, what about board edge shape, do we need to make it round or 90 degree is ok?

Regards,

beamray , 05-12-2020, 06:36 AM

1) in AD go to PCB editor, than press 1 on keyboard. double click on one of the rigid substacks. Check "3d locked"

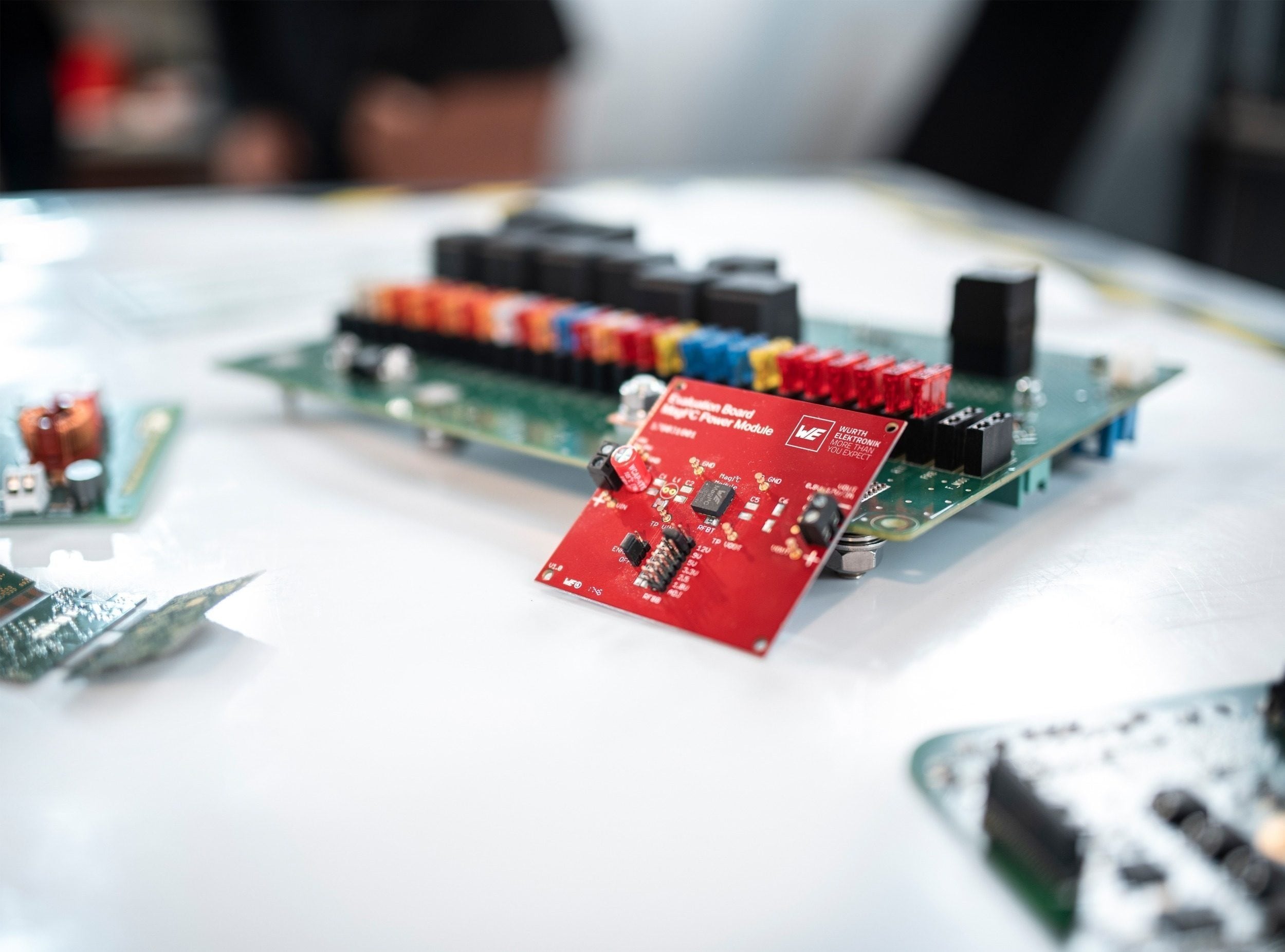

2) I can suggest “IRZ-FOTON” (https://en.irz.ru/company/32/113.htm), Tehnoteh in Russia , there is Wurth electronik in Germany and also I know Zebra PCB and CUBE CZ in Czech Republic. Chine: king field PCB Electronics Co.LTD (ask for Mila Wu), HoYoGo Pcb (ask for Yumi Yu). I do not recommend Ncab group, but I hope that i had bad luck no more. ( ones in bold are my favourite)

3) It is preferred to, they may suggest you how to make it cheaper.

4)Board shap can be almost what ever you would like, but it is highly recommended to make arks in flex part, there it is "connecting" with rigid part. Min Radius is 1.6mm. But it is nessesary only when your flex part is less wide than rigid.

Nice guides:

2) I can suggest “IRZ-FOTON” (https://en.irz.ru/company/32/113.htm), Tehnoteh in Russia , there is Wurth electronik in Germany and also I know Zebra PCB and CUBE CZ in Czech Republic. Chine: king field PCB Electronics Co.LTD (ask for Mila Wu), HoYoGo Pcb (ask for Yumi Yu). I do not recommend Ncab group, but I hope that i had bad luck no more. ( ones in bold are my favourite)

3) It is preferred to, they may suggest you how to make it cheaper.

4)Board shap can be almost what ever you would like, but it is highly recommended to make arks in flex part, there it is "connecting" with rigid part. Min Radius is 1.6mm. But it is nessesary only when your flex part is less wide than rigid.

Nice guides:

JohnsonMiller , 05-12-2020, 08:42 AM

@beamray , thank you for your help.

JohnsonMiller , 05-15-2020, 03:10 AM

I was wondering how should be the fiducial placement? Shall we put three fiducial on each rigid section?

JohnsonMiller , 05-15-2020, 02:09 PM

@beamray , I just finished my design and generate Gerbers, but assembly is the next question, we need to keep the rigid section in place to solder components, hand sodering may help, but of course for small numbers of boards and again fixing rigid section is needed. Building a special fixture does not make sense, and it sounds remaining solution is the rigid frame.

Would you explain how we can implement it in Altium?

Does rigid frame allow to implement and see the 3D bendings or block it.

Would you explain how we can implement it in Altium?

Does rigid frame allow to implement and see the 3D bendings or block it.

beamray , 05-15-2020, 02:43 PM

When board's assembly is complicated, or somthing is being soldered in pcb banded position we do metal templates.We also do flat metal templates when we can not use PCB frame (when PCB is so big that all is left is technological fabricators frame) or when heat sink is needed for soldering.

BUT most of times you should do PCB frame.

You see, when PCB is being made it is bigger than your pcb, This is cold panel . Panel can contain single PCB or multiple PCBs, and they can be any kind of PCBs. PANEL contains PCB it self, test coupons and technological frame. All of it is made together. Your PCB in soime stage will be milled or cut out from panel. and some times PCB is holding to FRAMe with necks.

What you need to do is create panel with your PCB (assembly panel) within fabrication panel.

https://static.electronicsweekly.com...el-example.jpg (https://www.electronicsweekly.com/bl...-part-2014-02/)

https://icape.libellab.eu/flexrigid2/ - nice demo

Ho[e it will help.

I usually draw assembly panel in mechanical layer and make Notes in FabNotes layer, frame layer, board shape layer and in PCBs drawing (documentation). Note says "PWB should be dispatched within assembly panel. Panel drawing data should be extracted from *Name of gerber*" ,you also should specify do you want a V-cut (and what kind of it of do you want neckdowns. Your assenbly house should tell you by what means they can get out your PCB from Panel. Of course, It would be better is you do fabrication and assembly in same place, so locals do the works and not you.

Use our interactive Discord forum to reply or ask new questions.